Introduction

Hydrothermal Synthesis method involves using any one of the many techniques to crystallize substances. Nanotechnology is one of the most critical factors in it.

Because technology progress takes us closer to becoming more innovative. Advanced sciences rank nanotechnology as one of the driving forces with the potential to revolutionize material science of the current age. For the synthesis of nanoparticles, the process of the hydrothermal method is being increasingly favored globally, by industries and R&D labs alike.

Fundamentals of Hydrothermal Synthesis Method

Hydrothermal synthesis method involves using any one of the many techniques to crystallize substances. It usually does at a high vapor pressure level and using a high-temperature aqueous solution; hence it is termed as ‘Hydro’ + ‘Thermal’ = Hydrothermal method. We have observed natural process for more than 800 years now and the term has geological origins.

In easy terms, hydrothermal synthesis described as an artificial way to synthesize single-crystal (nanoparticles). Also, It depends on the solubility of aqueous solution under hot water and higher temperature levels. A strong container within the hydrothermal reactor ‘Autoclave,’ and fill with a solution. The process wants constant maintenance of temperature difference between the opposing ends of the crystallizing compartment.

The end with higher temperature is wherever the solvent dissolved. While in the other end, which is comparatively cooler, where the nanoparticle growth takes place.

How Hydrothermal Synthesis Method for Nanoparticle Synthesis works?

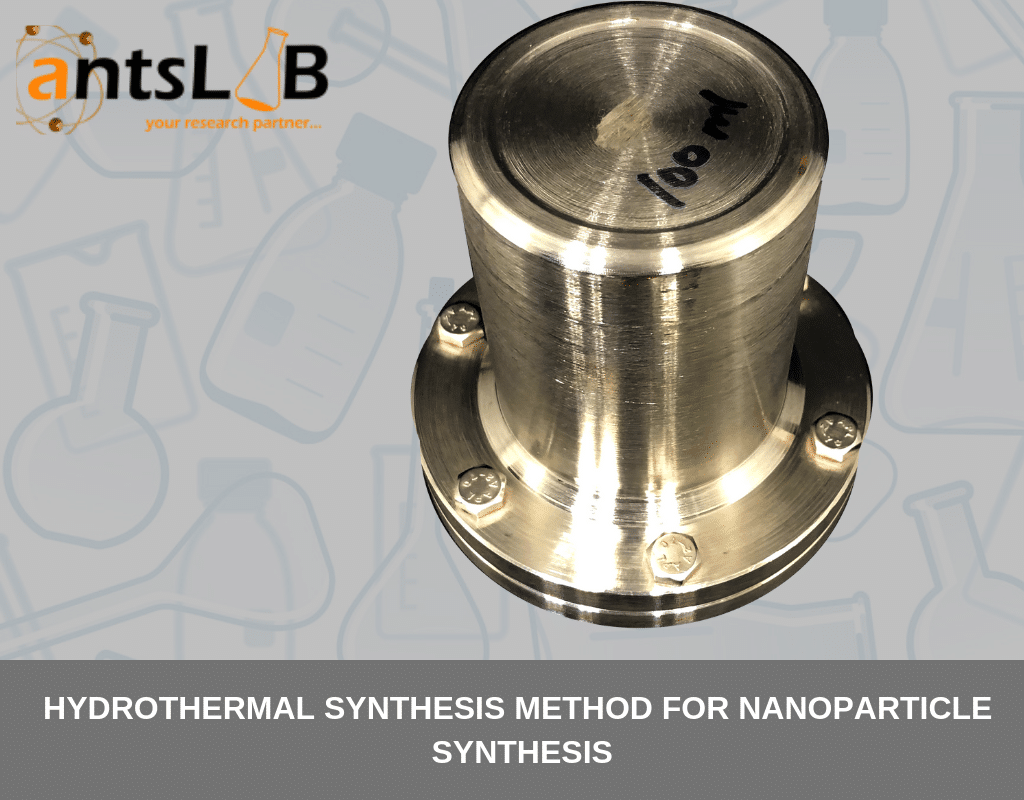

Hydrothermal technique for nanoparticle synthesis needs using special instrumentation, called Hydrothermal Autoclave Reactor. It is a specific style of strong vessel that we intend to face up to high temperatures and better pressure levels from within.

The autoclave reactor consists of thick and steel-walled cylindrical vessels having hermetic sealing. Likewise, this helps it to bear high levels of heat and pressure regularly and safely, for a long time. Also, the fabric of the autoclave also must be resistant to solvents. While the most vital part of the hydrothermal autoclave reactor is probably the ‘closure’. Apart from this, the seals are a successive necessary part of the autoclave.

As many hydrothermal processes need to use solutions having a corrosive impact on the interior material of the autoclave. Also, we apply special protective coatings to prevent corrosion. Because we usually design to suit the interior of the autoclave seamlessly and can either cover the entire interior of the autoclave or part of it.

Want to learn How To Use Hydrothermal Autoclave Reactor

These protective coatings usually made of gold, platinum, silver, carbon-free iron, titanium, glass or copper and Teflon. The specific style of protective layer will depend on the solution and the temperature utilized in the individual hydrothermal synthesis method.

Advantages of Hydrothermal Synthesis Method for Nanoparticle Synthesis

These are some of the top advantages and advantages of using hydrothermal nanoparticle synthesis methodology, as compared to other ways, for crystallization and synthesis of nanomaterials:

- Able to produce crystalline phases which aren’t stable at higher temperatures safely.

- Grows materials which are known to have a higher vapor pressure as their melting point gets closer.

- Creates larger-sized and high-quality crystals and nanoparticles, with control over their content and composition.

Finally, we hope that this article can be sufficient to offer you a clear plan of how the hydrothermal synthesis method for nanoparticle synthesis works truly.

This article helped us to know about the Hydrothermal process.