KBr Pellet Preparation or sample preparation the most important part for IR spectroscopy. Sample should be transparent to IR radiations so it allows the radiations to pass through them. So salts like KBr, NaCl, AgCl are used for mixing of sample in order to obtain the accurate IR spectrum of a sample with sharp peaks, good intensity with high resolution.

For powdered samples one of the way is to disperse it in Infrared Transparent medium such as Potassium Bromide (KBr) by pressing it into disc.

Typical Conditions for KBr sample preparation:

100:1 Kbr to sample ratio ( by weight)

13 mm Pellet Die

10 ton pressing load

While 7 mm pellet for FTIR applications for as little a 2 tons.

Though various techniques for the sample preparation exists here we will discuss the Pressed pellets Technique for solid samples.

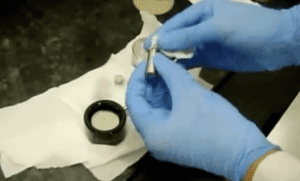

- Firstly we clean all the parts of die with chloroform or lubricant spray ( we use wd 40 ) thoroughly to get rid of any dirt and dry them with tissue.

2. Clean the mortar and pestle with chloroform or acetone thoroughly to get rid of any dirt and dry them with tissue.

3. Transfer a speck of sample into the mortar. Be careful of not adding too much sample which may cause over saturation.

4. Scoop out dry KBr into the mortar. Grind using the pestle. Continue for a minute or two to get a homogenous mix.

Note: Do not crush the potassium bromide to very finely powder as reduced particle size or fine powder of potassium bromide tends to gain moisture from the environment due to its hygroscopic nature and forms the bands in certain IR region.

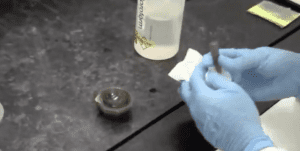

5. Fix the Pellet Press together. Insert the die into the cavity.

6. Transfer the ground sample mix into the cavity using a metal spatula. Make sure it’s evenly spread. Depending on the thickness of pellet we want to achieve we put the amount of powder. Putting excess makes it more thick.

7. Insert the bolt press and rotate into the cavity to distribute the particles.

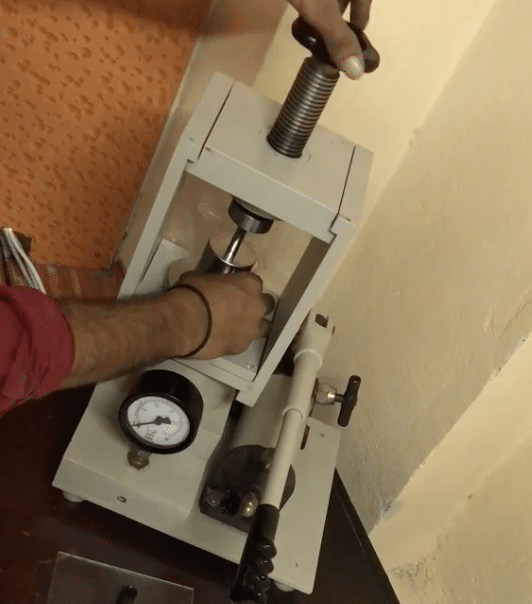

8. Transfer the whole die set to the hydraulic pellet press and rotate the wheel to secure it tightly.

9. Close the valve of the hydraulic press. Pull the level to put pressure until handle becomes tight. To release the die first need to loosen the pressure, then move up the upper wheel of the press and then take out the die.

10. Take out the bottom Plunger and place the die in the ejector. Apply pressure to release the pellet from the die.

If you are doing XRF and want to avoid metal contamination such as iron in stainless steel body then you can opt for tungsten carbide lined dies. Diameters from 3 mm to 30 mm is available. Smaller diameter are generally used to FTIR and larger diameter are for XRF.

Product Links:

Please send me quotation for FTIR hydraulic press of 10 ton

Dear Sir,

Please drop a mail to sales@antsceramics.com for quotations.

Regards,

Team Ants