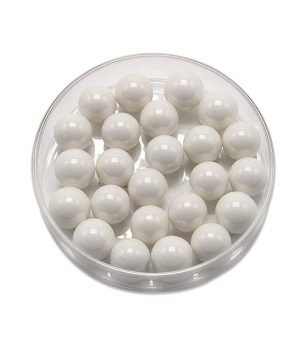

Ceramic Balls / Alumina Balls are highly efficient grinding media for Attritors and Ball mills. Because these are suitable for dry and wet grinding in ball mills.

For Grinding Applications in.

- Ceramic.

- Paints and Primers.

- Minerals Cement.

- Plastic.

- Food and Biotech.

The advantages of alumina balls or ceramics balls compare to steel balls.

- Harder than steel in wear resistance.

- Eliminate iron contamination.

- Low heat built up.

- Non-corrosive.

- Lower density and higher hardness offer energy saving.

- Extended mill life.

- Reduced Noise pollution Typical Properties.

- Chemical Composition Al2O3 92% SiO2 5%

Typical Properties of Ceramic Balls ( Alumina).

- Chemical Composition Al2O3 92%

- SiO2 5%

- Others 3%

- Specific Gravity (g/cc) 3.6%

- Bulk Density (g/cc) 2.2%

- HV Hardness 1250

- Shape Round

- Colour White

Most Important key properties of grinding media are size, density, hardness and its composition. We have expertise in grinding and milling processes. Similarly, we can recommend the best-suited grinding and milling media material size and quantity for your application.

Ants offer a wide variety of grinding balls.

The selection of grinding media depends on many most important factors as stated below:

Initial and final particle sizes of the materials – The size of grinding balls should be selected based on the initial and final particle sizes of the material.

Density – Grinding media with higher density usually have better milling efficiency and can lead to the smaller final particle size of the material to be ground. The media should have higher specific gravity than the material which is to be milled.

Hardness – Harder media have higher wear resistance, less contamination and thus better milling efficiency.

Composition – The selection of media composition depends on the compatibility with the material to be milled. and also the container and liner materials used in the milling process. Because the goal is to minimize contamination during milling and yet to achieve the best milling effect.

Cost – Zirconia milling media typically have a higher cost than alumina and agate milling media. However, they are also more wear resistant and provide better milling efficiency. therefore, the actual milling costs can be lower even though the grinding media cost is higher.

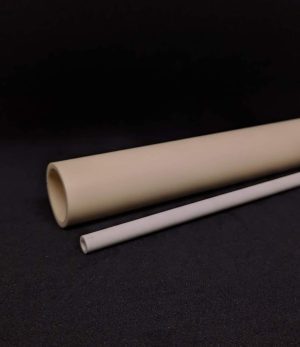

We also offer Zirconia Grinding Media

Reviews

There are no reviews yet.