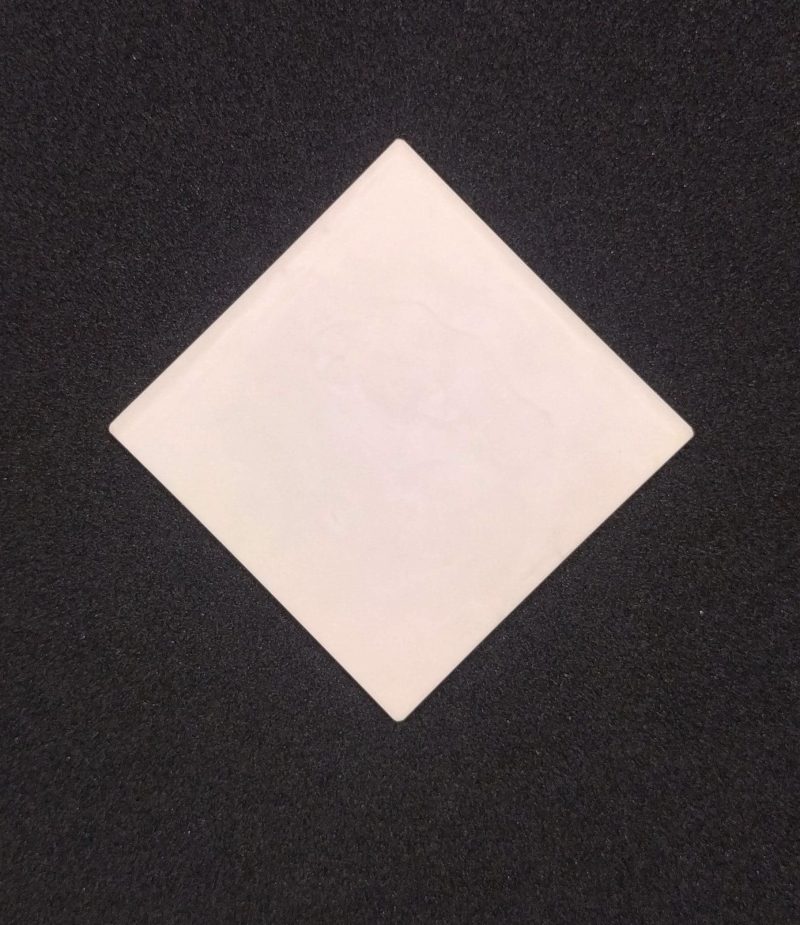

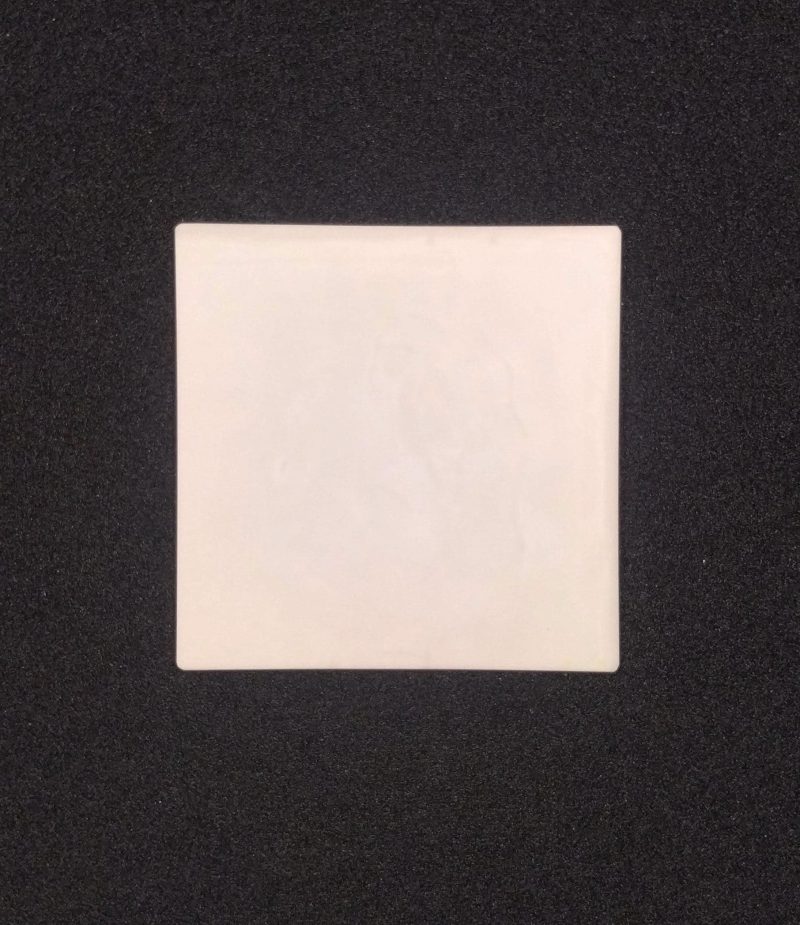

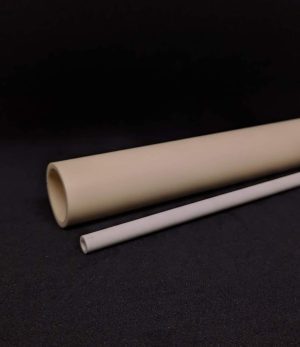

Our alumina substrate has well-balanced properties of insulation, thermal conductivity and breaking strength. Moreover, one of the unique properties is its surface roughness. We can provide the ceramic substrate which is excellent in adhesion with a thin film and thick film metallization due to fine particles. We severe quality control with carefully selected high purity ceramic materials that ensures stable quality and excellent properties, therefore, we are the first choice in ceramics products for the customers.

Thin-film ceramic substrate uses Alumina for most applications Because of Its excellent heat resistance, high mechanical strength, abrasion resistance and small dielectric loss. Even More, the surface of the alumina substrate 99.8% is quite smooth and low porosity. Moreover, Alumina substrate 99.7% is also suitable for thin film device and for thick film device application.

Ants provide alumina ceramic substrates for the following applications

- Thin film and thick film microelectronic.

- High power and high-frequency circuit.

- RF/microwave components and capacitor or resistor.

The technical specifications of Alumina substrates 99.7%

- The Appearance and colour of Alumina Substrate 99.7% are Dense and white.

- Alumina substrates Content 99.7% Al203.

- The Bulk Density is kg/m3 3.7 x 103.

- Water Absorption is 0%.

- Vickers Hardness is 13.7 GPa.

- Flexural Strength is 350 MPa.

- Young’s Modulus 320 GPa.

- The coefficient of Linear Thermal Expansion is 7.2 x 10-6/°C (40-400°C) and 7.9 x 10’rC (40-800’C).

Shop High-Purity Alumina substrate 99.7% by AntsLAB™ manufactured and quality controlled to ensure stable quality and excellent characteristic. We offer high-quality silicon substrate product which is mostly used worldwide for the production of microchips.

Reviews

There are no reviews yet.